欢迎访问小鸭集团官方网站

端径跳在线检测仪说明书 |

MANAUL OF AUTOMATIC ONLINE TESTING MACHINE |

MODEL JCJ13-18AH |

SHANDONG XIAOYA PRECISE MACHINERY CO., LTD |

2. 概述 Summary

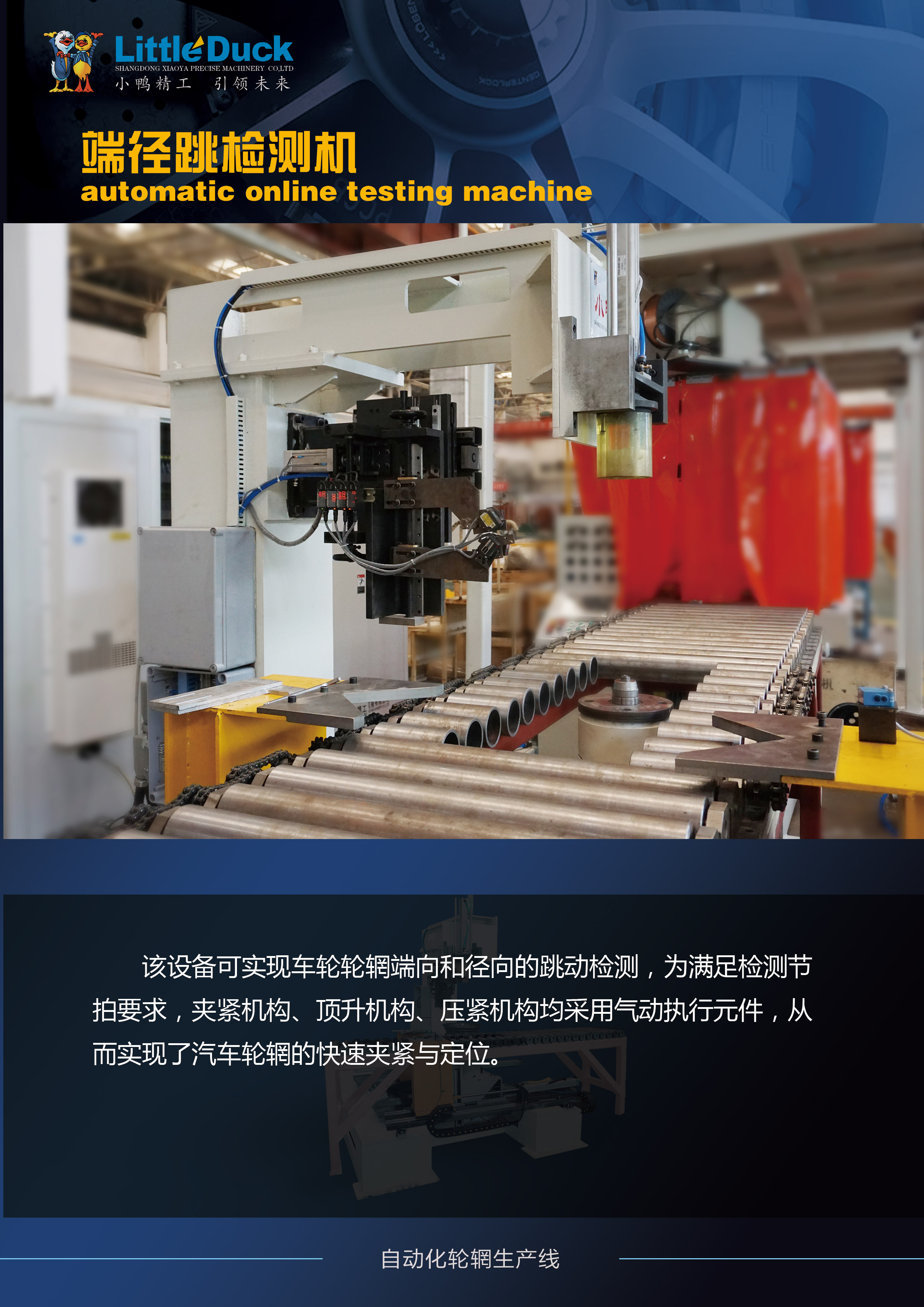

该设备可实现车轮轮辋端向和径向的跳动检测,为满足检测节拍要求,夹紧机构、顶升机构、压紧机构均采用气动执行元件,从而实现了汽车轮辋的快速夹紧与定位。

This equipment can realize test for radical run-out and axial run-out of wheel rim. To satisfy requirement to test tact, the clamping device, jacking device and pressing device all use pneumatic actuator, which can clamp and locate rim quickly.

工件从上一工序到达本工序,传送到预定位置,检测开关检测到工件,夹紧机构将工件送到检测位置下方,顶升夹紧机构将工件顶起并夹紧定位,压紧机构将工件压紧,伺服电机旋转带动工件旋转,检测机构检测工件,检测完毕后合格产品通过传送机构传送到下一工序,对于不合格产品可通过后面的分选机构分选。

The workpiece from last process of fitting-press machine to this process will be conveyed to the appointed position, workpiece will be detected by detecting switch and will be conveyed below detection position by clamping device. The jacking device will jack workpiece up, clamp it and locate. Pressing device will press the workpiece. Servo motor rotates to drive workpiece rotation. The testing device will test workpiece. After test the qualified product will be conveyed to next process by transmission device, and the unqualified one will be selected out by the selecting mechanism.

该设备实现了过程的自动化与检测数据的可视化,达到稳定产量、提高质量、降低消耗、高效实用的目的。

This equipment realizes automatically production process and visual testing data. It achieved target of constant production, quality improvement, consumption reduction and high efficiency and pragmatic function.

3.规格参数Specification

设备型号 | Model Number | Номер модели | JCJ13-18AH |

电网电压 | Power Supply | AC 380V, 3phase, 50Hz | |

轮辋最大宽度 | Rim Max. Width | 290mm | |

轮辋最小宽度 | Rim Mini. Width | 120mm | |

压缩空气 | Compressed Air Pressure | 0.4~0.6Mpa | |

轮辋最小直径 | Rim Mini. Diameter | 12 inches | |

轮辋最大直径 | Rim Max. Diameter | 18 inches | |

中心孔定位精度 | Position Accuracy of Centre Hole | 0.03mm | |

主轴自身径跳精度 | Radial Runout Accuracy of Spindle | 0.03mm |

4.设备结构简介Equipment Structure Introduction

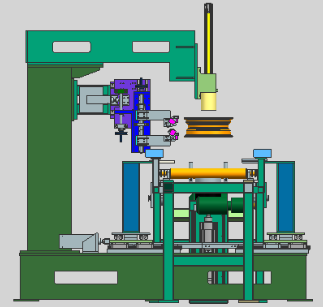

该设备包括控制系统、上料系统、检测系统和分选系统四大部分;主要由1传送机构、2夹紧机构、3顶升旋转机构、4压紧机构、5检测装置、6分选机构等组成;

This equipment can be divided into four parts: control system, feeding system, testing system and selecting system. It mainly consists of transmission device (1), clamping device (2), jacking-rotating device (3), pressing device (4), testing device (5), selecting device (6), etc., shown as below pictures.

结构示意图1 /Structure Sketch 1 |

|

|

可实现自动送料机构同生产线连接,该设备能自动将工件输送到预定工位,夹紧机构夹紧工件并输送到检测区,顶升机构定位找正并将工件抬起、压紧机构将工件压紧、顶升旋转机构带动工件旋转,检测装置在线检测。

Its automatically feeding device can be connected with production line. This equipment can convey workpiece to the appointed processing position automatically. Clamping device grips workpiece and conveys it to testing part. Jacking device locates and lifts workpiece up. Pressing device presses workpiece, jacking-rotating drives workpiece to rotate and testing device will do the online testing operation.

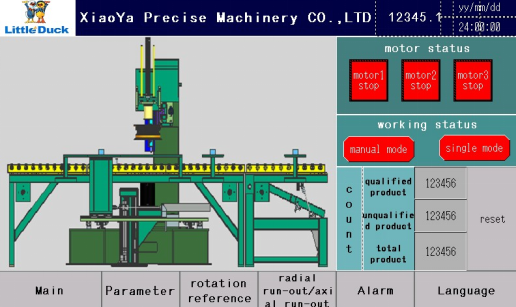

点击“主界面”进入上图画面,左边为设备整体正面截图,右边为滚道各个部分的运行状态,操作模式,产品合格数与不合格数的对比。

click “main” to get into interface like above picture. The left part is equipment’s front view; the right side is the running condition of slide way’s every part, operation mode and the quantity comprehension between qualified product and unqualified product.

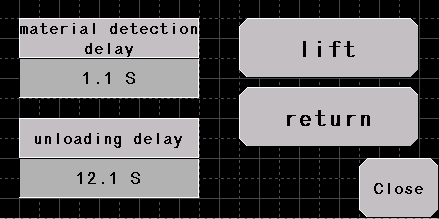

点击“操作调整”,弹出上图画面,设置入料检测延时和卸料延时,准确的把握整个设备的工作节拍,顶升气缸的升起落下点动按钮,用于调试动作,调整夹手,更换模具。

Click “parameter” button to get the interface like above picture, where can set material loading detection delay time and unloading delay time. Precisely hold the working tact of whole equipment. The “lift” button of jacking cylinder is used to adjust action,

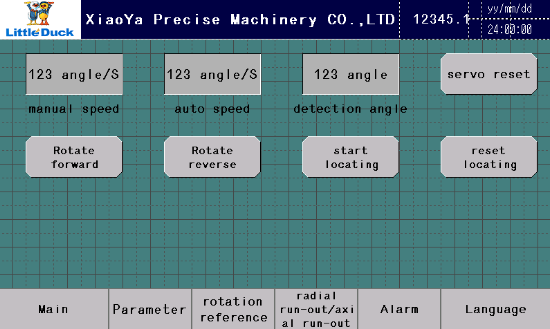

点击“旋转参数”,进入上图画面,设置手动旋转的速度,自动或定位旋转的速度,定位旋转的角度,伺服复位按钮,主轴正转反转旋转按钮,手动定位按钮,位置归零按钮(把当前位置设置为零点)。

Click “rotation reference” to get into the interface like above picture, where can set manual rotation speed, auto or locating rotation speed, locating rotation’s angle, servo reset, main spindle rotation forward or reserve, manual locating, position to zero (set current position as zero position).

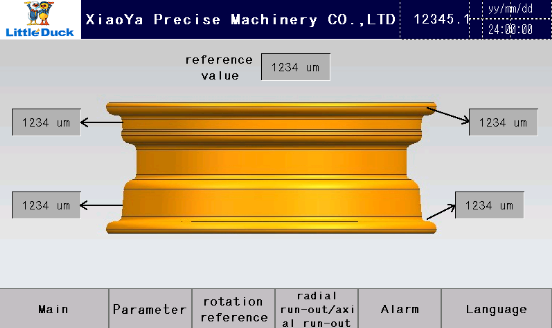

点击“端跳径跳”,进入上图画面,可以看到探头测到的每个位置的跳动误差,还可以设置一个参考数值,每次测完与这个参考数值作对比,四个位置的跳动误差都小于这个参考数值说明产品合格,否则产品不合格。

Click “radical run-out/axial run-out” to get into interface like above picture, where can check the run-out error of each position detected by probe, also can set a reference value. Every time after testing can compare it with reference value, if the run-out error of four positions are all smaller than reference value, the product is qualified, otherwise the product is unqualified.

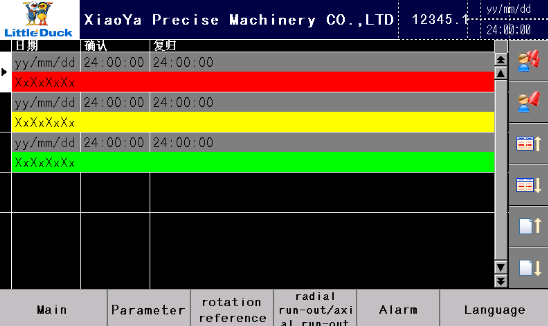

点击“报警界面”显示上图所示画面,当有报警显示时,这个按钮会变成红色,点击进入会看到相应的报警信息。

Click “alarm” to get into the interface like above picture. When alarm occurs, this button will become red, click it and get into interface can check corresponding alarm information.

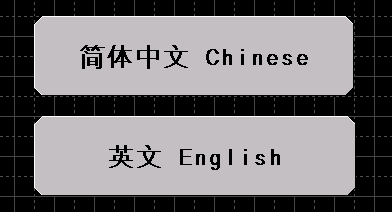

点击“语言切换”出现上图弹出式图画,在中英文之间切换。

Click “language” to get into interface like above picture, where can choose language between Chinese and English.

分支机构

山东小鸭集团智能电器有限公司山东小鸭精工机械有限公司山东小鸭冷链有限公司山东小鸭集团家电有限公司山东小鸭小家电有限公司山东小鸭集团洗涤机械有限公司山东小鸭新能源科技有限公司山东小鸭智能电器有限公司济南泺安物业管理有限公司新闻中心

新闻中心联系我们

电话:400-658-6222 邮编:250000 地址:山东省济南市工业南路51号 国际贸易部:+0086-531-83122097 邮箱:xiaoyalogo@xiaoyagroup.com.cn鲁ICP备10021990号-1 | © 2018 山东小鸭集团有限责任公司 版权所有 |  鲁公网安备 37010202000910号

鲁公网安备 37010202000910号